Use and Reuse (OnOffice)

For almost 100 years, Norwegian furniture manufacturer Fora Form has been shaping the spaces where people work, meet and connect. Now, under the stewardship of Heidi Lyngstad, its ambitious Fora ReForm initiative is redefining longevity for the next century

When 17-year-old Jens E. Ekornes and 18-year-old Peter P. Langlo founded a furniture business in 1929, they couldn’t have imagined the legacy they were building. Almost a century and several name changes later, Fora Form remains anchored in Ørsta, a small village in Norway’s Sunnmøre region, still guided by its mission "to create furniture with good design for places where people meet”. Katie Treggiden meets Head of Sustainability Heidi Lyngstad to explore how she is future-proofing that legacy for the next 100 years.

What is Fora Form’s approach to furniture?

Our focus is always on the contract market. This defines our approach to materials, quality, and product strength. Our ambition is for our furniture to contribute to environments that foster meaningful, open and inspiring encounters, whether in workplaces, canteens, restaurants, libraries, or lobbies.

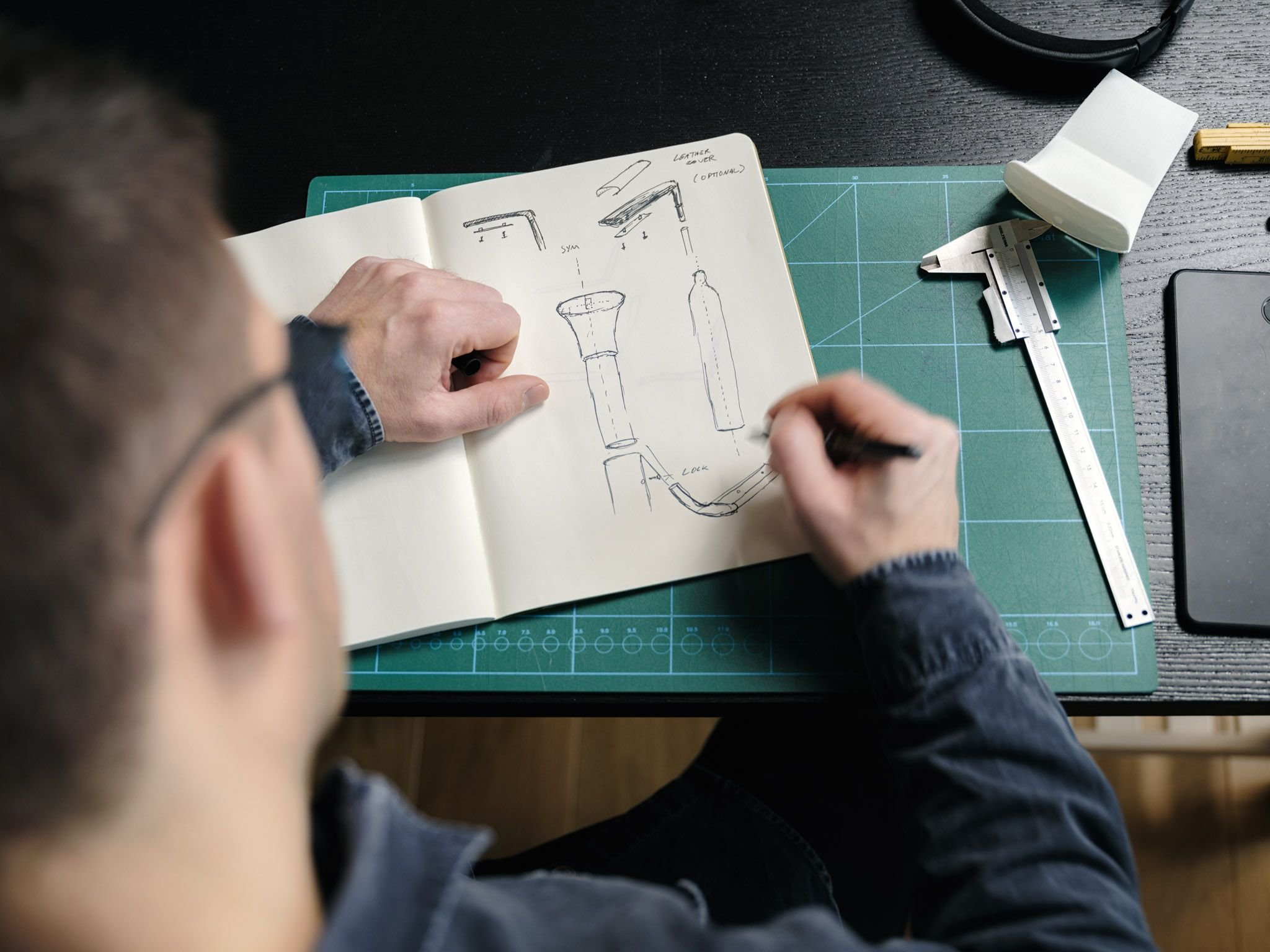

What do your collaborations with leading designers such as Lars Tornøe, Nesset & Strand and Hunting & Narud bring?

Collaborating with external designers helps us stay relevant and inspired by what is both functional and forward-looking. This strengthens our professional expertise and broadens our perspective. The designers we work with range from recent graduates to those with decades of experience, which means our role varies from project to project, and no two development processes are the same.

Your Fora ReForm initiative enables clients to upgrade and renew used Fora Form furniture. How does it work?

We noticed that the market is full of older Fora Form products at risk of being discarded simply because of worn textiles or damaged components. The common denominator is that the product remains solid—testament to their quality and durability—but, inevitably, time has left its mark. We wanted these products to have a continued life, so we created a programme through which parts, components and upholstery can be replaced. By using Fora ReForm, customers receive a renewed 5-year warranty and a new EPD (Environmental Product Declaration) documenting the environmental benefits of refurbishing an existing product, for example, 30–50% of the emissions compared to a new one. All the practical work, such as upholstery, component replacement and transport, is handled by certified local partners.

How do you assemble your local partner network?

It was important to ensure geographical coverage across regions, so that transport distances, and therefore carbon, could be minimised. We reached out to partners all over Norway who are known for their craftsmanship and professionalism—and they all said yes! They have since told us that partnering with a company like Fora Form is beneficial for them too. Fora ReForm has been very well received with clients and customers, and the refurbished products get excellent feedback.

How has the programme had an impact on sales?

You might think that offering refurbishment would cannibalise sales of new products. For instance, a customer buys ten new Fjell chairs from us in 2025, confident that in 2035, those chairs can be renewed—with new upholstery and a fresh 5-year warranty—effectively providing the experience of a new product. While this may have a short-term impact on sales, we see it as a way to strengthen our reputation as a solid and responsible manufacturer, build customer loyalty, and attract new customers who value sustainability and accountability. A growing secondary market for reused furniture is also emerging, and our ReForm concept ensures that we can actively participate in this segment as well.

What other steps does Fora Form take to be a responsible business?

We have been manufacturing quality furniture for nearly 100 years, with a focus on creating lasting value. We have long been a cornerstone company in Ørsta, Norway, and take good care of our employees, many of whom have worked with us for 40 years or more. We choose our partners carefully, working locally whenever possible. Our ISO certifications ensure we continuously improve quality, sustainability, and working environments—to the benefit of both people and the planet. Our products are certified according environmental labelling schemes such as Svensk Møbelfakta and the Nordic Swan Ecolabel, and we strive to have EPDs for all our furniture series, which offers transparency for both us and our customers. And, like most reputable Norwegian companies, we are a member of voluntary packaging scheme Grønt Punkt Norge (Green Dot Norway), which means we pay a fee based on the amount of packaging we place on the Norwegian market, contributing to its collection and recycling.

What do you wish the rest of the furniture industry would learn or change?

The most sustainable way to produce furniture is to focus on high quality and well-considered design that ensures longevity. By working with reputable suppliers committed to responsible business practices and minimising their environmental footprint, we can help create positive ripple effects throughout the entire value chain. It is also a significant advantage to take ownership of the product’s entire lifecycle, as we do through our ReForm concept, offering spare parts and upholstery for products to keep them in use long after they have been produced.

All copy is reproduced here as it was supplied by Katie Treggiden to the client or publication.

Katie Treggiden is a craft, design and sustainability writer, a nature facilitator and the author of Broken: Mending and Repair in a Throwaway World (Ludion, 2023).